manual hand pump for well

- by gage

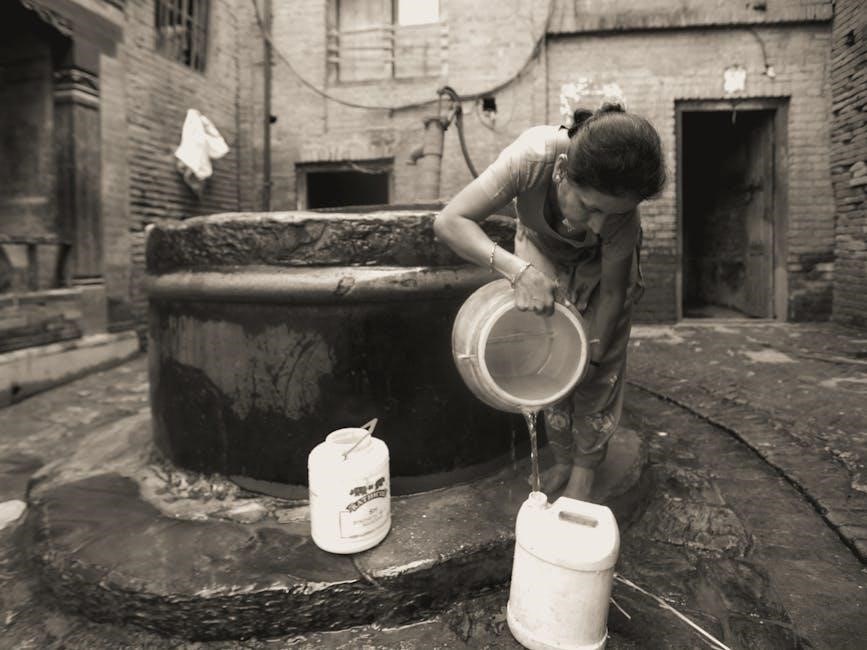

Manual hand pumps are essential tools for extracting water from wells, offering a reliable, eco-friendly solution for accessing water without electricity. They provide consistent water supply during power outages, making them vital for sustainable and off-grid living.

1.1 Definition and Purpose

A manual hand pump for wells is a device operated by hand to extract water from underground sources. It functions without electricity, relying on mechanical effort to draw water to the surface. Designed for reliability, these pumps are ideal for residential, agricultural, or emergency water needs. Their purpose is to provide a sustainable and eco-friendly solution for accessing water, especially in areas with limited power supply or during outages. They ensure consistent water availability, making them a vital tool for off-grid living and water independence.

1.2 Importance of Manual Hand Pumps in Water Supply

Manual hand pumps play a crucial role in ensuring a reliable water supply, especially in rural or off-grid areas. They provide a consistent source of water during power outages, making them indispensable for emergency preparedness. These pumps are eco-friendly, cost-effective, and durable, offering a sustainable solution for water access. Their simplicity and low maintenance requirements make them ideal for communities with limited resources, ensuring access to clean water for drinking, irrigation, and other essential needs. They are a vital component of water security and self-sufficiency.

Types of Manual Hand Pumps

Manual hand pumps come in various designs, including lever-operated, rotary-style, and screw-operated models, each offering unique advantages for different water extraction needs and environments.

Lever-operated pumps are a popular choice for manual water extraction, utilizing a simple mechanism where a lever is moved up and down to create suction. This design is known for its reliability and ease of use, making it ideal for shallow wells. The lever’s motion activates a piston, drawing water through a cylinder and check valves, ensuring efficient water flow. Their durability and low maintenance make them a preferred option for many households and communities relying on well water. Rotary-style pumps operate using a circular motion, where turning a handle drives a rotating shaft connected to a piston or gear system. This design provides consistent water flow and is often preferred for its efficiency in deeper wells. The rotary mechanism reduces fatigue compared to lever-operated models, making it easier to pump water over extended periods. Its durability and smooth operation make rotary-style pumps a practical choice for both domestic and communal water supply needs, especially in areas with moderate to high water demand. Screw-operated pumps use a screw mechanism to draw water from the well. As the handle is turned, the screw engages with the water, lifting it to the surface. These pumps are known for their simplicity and low maintenance, making them ideal for shallow wells. They often feature dual check valves to ensure efficient water flow and prevent backflow. Screw-operated pumps are durable and reliable, providing a consistent water supply with minimal effort. They are a practical choice for small-scale water needs and emergency backup systems. Manual hand pumps operate by converting mechanical energy into hydraulic energy. As the handle is moved, a piston draws water from the well through check valves, ensuring efficient extraction. Manual hand pumps extract water through a simple yet effective mechanism. When the handle is moved up and down, a piston inside the cylinder creates suction, drawing water from the well. As the piston rises, it lifts water through check valves, which prevent backflow. This continuous motion ensures a steady water supply. The process relies on the user’s physical effort, making it a sustainable solution for wells. Regular maintenance is crucial to keep the pump functioning efficiently and ensure consistent water extraction. Check valves are crucial components in manual hand pumps, ensuring water flows in one direction. As the piston moves downward, the check valve opens, allowing water to rise through the pump. When the piston lifts back up, the valve closes, preventing water from flowing back into the well. This mechanism maintains consistent water extraction and prevents energy loss. Properly functioning check valves are essential for efficient pump operation, ensuring a steady water supply with minimal effort required from the user. Proper installation ensures efficient operation and longevity of manual hand pumps. It involves selecting a suitable site, preparing the well, and aligning the pump correctly for optimal water extraction. Selecting the right site for a manual hand pump is crucial for effective water extraction. The area should be level and close to the well to minimize effort. Clear the site of debris and vegetation to ensure proper installation. Prepare the well by ensuring the casing is secure and the water level is accessible. Proper site preparation prevents future issues and ensures the pump operates efficiently, providing a reliable water source. Installing a manual hand pump involves several precise steps. Begin by attaching the pump cylinder to the well casing, ensuring a secure fit. Next, connect the suction pipe and check valves, making sure they are properly aligned. Install the handle and lever system, then test the pump by priming it with water. Finally, secure all connections and perform a functionality test to ensure smooth operation. Proper installation guarantees efficient water extraction and longevity of the pump. Regular maintenance ensures optimal performance and extends the lifespan of manual hand pumps. Inspect and clean components, lubricate moving parts, and replace worn-out seals or valves promptly. Routine maintenance is crucial for ensuring the longevity and efficiency of manual hand pumps. Regular tasks include inspecting and cleaning the pump components, lubricating moving parts, and checking for wear and tear on seals and valves. It is also important to ensure the pump is properly aligned and secured to prevent misalignment issues. Additionally, periodic testing of the pump’s performance can help identify potential problems early, allowing for timely repairs and preventing costly downtime. Consistent upkeep ensures reliable water access. Common issues with manual hand pumps include leaks, low water flow, and worn-out parts. Leaks can often be fixed by replacing worn seals or O-rings. Low water flow may result from a clogged intake screen or faulty check valves, which should be cleaned or replaced. Regular lubrication of moving parts and inspecting for misalignment can prevent premature wear. Addressing these issues promptly ensures optimal performance and extends the pump’s lifespan, maintaining reliable water access for users.

Manual hand pumps are reliable during power outages, cost-effective, and durable, ensuring consistent water access without electricity, making them ideal for off-grid and emergency situations. Manual hand pumps provide consistent water access during power outages, ensuring hydration and hygiene needs are met. Their non-electric operation makes them indispensable in emergencies, offering a sustainable solution for off-grid living. This reliability is crucial for households and communities reliant on wells, as they eliminate water scarcity risks during outages. By maintaining functionality without electricity, manual pumps serve as a vital backup system, enhancing overall water security and preparedness. Manual hand pumps are a cost-effective solution for well water extraction, requiring minimal initial investment and maintenance. Their durable construction ensures long-term reliability, withstanding harsh environmental conditions. Unlike electric pumps, they operate without electricity, reducing operational costs and dependency on power. This makes them a practical choice for remote or off-grid locations. Their simplicity and robust design contribute to extended lifespan, providing consistent water access while minimizing financial burden over time. This combination of affordability and resilience makes manual pumps a sustainable option for water supply needs. Manual hand pumps require physical effort and are limited by water depth, making them less efficient for deep wells or high-demand scenarios. Manual hand pumps demand significant physical effort, requiring repetitive motion and strength, especially for deep wells. This can lead to fatigue and is less efficient for large water needs. Manual hand pumps are limited in the depth from which they can extract water, typically effective up to 20 meters. Beyond this, the suction lift becomes inefficient, making electric pumps more suitable for deeper wells. This restriction affects their usability in areas requiring access to deeper water sources, highlighting a key limitation in their application. Proper usage and maintenance of manual hand pumps are crucial to ensure safe water extraction and prevent contamination. Regular inspections and sanitized storage are essential for hygiene. Proper usage of manual hand pumps ensures efficient water extraction and longevity. Always operate the pump slowly and steadily to avoid damage. Regularly inspect the handle, piston, and valves for wear. Lubricate moving parts periodically to maintain smooth operation. Ensure the pump is installed on a stable, level surface to prevent tipping. Avoid overexertion, as excessive force can damage the mechanism. Follow the manufacturer’s instructions for maximum efficiency and safety. Proper usage guidelines help maintain water quality and prevent contamination. Preventing contamination is crucial for maintaining a safe water supply. Regularly clean and sanitize storage containers and the pump area to avoid bacterial growth. Ensure the pump is properly installed to prevent surface water infiltration. Use food-grade buckets for storage and clean them weekly. Avoid cross-connections between the pump and other water sources. Regular maintenance, such as checking for worn-out parts, helps prevent contamination. Proper usage and storage practices ensure the water remains clean and safe for consumption. Regular inspections are essential to maintain water quality. Manual hand pumps are a cost-effective solution for water extraction, offering long-term savings despite initial installation costs. They eliminate reliance on electricity, reducing operational expenses significantly. The initial cost of a manual hand pump for wells is often manageable, with durable materials ensuring long-term savings. While the upfront investment may seem significant, the absence of electricity costs and minimal maintenance requirements make it a cost-effective solution over time. For instance, models like the DCHP102 screw-in cartridge-style pump offer reliability and reduced long-term expenses. This balance of affordability and durability makes manual hand pumps a practical choice for sustainable water access. Manual hand pumps offer distinct advantages over electric pumps, particularly in reliability during power outages. While electric pumps require consistent electricity and can fail during blackouts, manual pumps provide uninterrupted water access. Although electric pumps may extract water faster, manual pumps are eco-friendly and cost-effective in the long run. They also eliminate the need for expensive electrical installations and maintenance, making them a sustainable choice for wells. This makes manual pumps a preferred option for off-grid and emergency water supply systems. Manual hand pumps are eco-friendly, operating without electricity or emissions, making them a sustainable choice for water extraction. They promote water conservation and reduce carbon footprints effectively. Manual hand pumps are inherently eco-friendly, requiring no electricity or fuel, thus producing zero emissions. Their operation relies solely on human effort, making them a sustainable option for water extraction. By eliminating the need for electricity, these pumps significantly reduce carbon footprints and contribute to environmental conservation. Additionally, they promote water conservation by ensuring minimal waste during use. Their simple, durable design often includes recyclable materials, further enhancing their eco-friendly profile and making them a responsible choice for well water access. Manual hand pumps promote sustainable water usage by allowing users to extract only the needed amount, reducing waste and conserving this vital resource. Their design encourages mindful consumption, fostering a culture of water stewardship. Unlike automated systems, manual pumps ensure that water is used efficiently, aligning with environmental goals. This sustainable approach supports long-term water resource management, making manual pumps a practical choice for eco-conscious communities and off-grid living. Their simplicity and effectiveness contribute to global water conservation efforts. Choosing between DIY and store-bought pumps involves weighing cost, convenience, and quality. DIY options offer affordability but require time and skill, while store-bought pumps provide reliability and warranties, ensuring durability and performance for long-term use. DIY installation of manual hand pumps offers cost savings and a sense of accomplishment but requires technical skills and time. While it can be budget-friendly, improper installation may lead to inefficiency or early wear. Additionally, sourcing quality materials is crucial to ensure durability. However, for those with experience, DIY projects can be rewarding and tailored to specific needs, providing a personalized solution for water extraction. Proper planning and execution are essential to avoid common pitfalls. Pre-made manual hand pumps offer convenience, reliability, and durability, ensuring optimal performance right out of the box. They are designed with quality materials and tested for efficiency, reducing the risk of installation errors. Many come with warranties, providing peace of mind. Additionally, pre-made pumps often include user-friendly designs and clear instructions, making them accessible even to those without DIY experience. This convenience can save time and effort, ensuring a hassle-free water supply solution for wells. Identify and resolve issues like leaks, low water flow, and pump malfunction by inspecting valves, checking connections, and ensuring proper installation and maintenance of the pump system. Leaks in manual hand pumps can lead to reduced efficiency and water waste. To identify leaks, inspect all connections, gaskets, and valves for visible water droplets or moisture. Common causes include worn-out seals or loose fittings. Fixing leaks involves replacing damaged gaskets or tightening connections. Regular maintenance, such as lubricating moving parts and checking for wear, can prevent leaks from occurring. Addressing leaks promptly ensures optimal pump performance and extends its lifespan. Always use compatible replacement parts for effective repairs. Low water flow from a manual hand pump can result from clogged screens, worn piston seals, or insufficient pumping effort. Check the intake screen for debris and clean it regularly. Inspect the piston and cylinder for wear, replacing seals if necessary. Ensure the pump is primed correctly and the well water level is adequate. If issues persist, consider adjusting the pump depth or checking for blockages in the piping. Regular maintenance and proper usage can help maintain optimal water flow and pump efficiency over time. Innovations in manual pump design include lightweight materials and ergonomic handles, enhancing efficiency and user comfort. Integration with smart sensors for real-time water level monitoring is emerging, improving functionality and sustainability. Recent advancements in manual hand pump technology include the use of lightweight, corrosion-resistant materials like aluminum and fiberglass, reducing weight and extending durability. Ergonomic handle designs improve ease of use, while innovative valve systems enhance water flow efficiency. Additionally, some modern pumps incorporate smart sensors to monitor water levels and pressure, ensuring optimal performance. These innovations aim to make manual pumps more user-friendly, efficient, and sustainable, addressing the needs of both urban and rural water supply challenges effectively. Manual hand pumps are increasingly being integrated with modern water systems to provide backup solutions during power outages. Hydraulic pumps, like the Milwaukee M18 Brushless, offer high-pressure capabilities, making them compatible with advanced systems. Dual-function designs allow seamless switching between manual and electric operation, ensuring continuous water access. This integration enhances reliability and flexibility, catering to both traditional and contemporary water supply needs while maintaining the simplicity and eco-friendly nature of manual pumps. Manual hand pumps for wells are reliable, eco-friendly solutions for water access, offering durability and cost-effectiveness. They ensure water availability during power outages, making them indispensable for sustainable living. Manual hand pumps for wells are reliable, eco-friendly solutions for water extraction, offering durability and cost-effectiveness. They ensure water access during power outages, making them ideal for emergencies. While they require physical effort and have depth limitations, their simplicity and sustainability make them a vital tool for rural and off-grid communities. Proper installation and maintenance are crucial for optimal performance, ensuring a consistent water supply. These pumps are a practical choice for those seeking independence from electric systems. Manual hand pumps are timeless solutions for water extraction, combining simplicity with effectiveness. They offer reliability during emergencies and are environmentally friendly. While they require effort and have depth constraints, their durability and cost-effectiveness make them invaluable. For those prioritizing sustainability and self-sufficiency, manual hand pumps remain an excellent choice, ensuring access to water without reliance on electricity. Their practicality and eco-friendly nature solidify their place as essential tools for modern and off-grid living. Reliable and durable manual hand pump for wells. Easy to use and maintain, perfect for rural areas. Posted in Manuals2.1 Lever-Operated Pumps

2.2 Rotary-Style Pumps

2.3 Screw-Operated Pumps

Working Principle of Manual Hand Pumps

3.1 Mechanism of Water Extraction

3.2 Role of Check Valves in Pump Operation

Installation of Manual Hand Pumps

4.1 Site Selection and Preparation

4.2 Step-by-Step Installation Guide

Maintenance and Repair

5.1 Routine Maintenance Tasks

5.2 Common Issues and Solutions

Advantages of Manual Hand Pumps

6.1 Reliability During Power Outages

6.2 Cost-Effectiveness and Durability

Challenges and Limitations

7.1 Physical Effort Required

7.2 Depth Restrictions for Water Extraction

Safety Considerations

8.1 Proper Usage Guidelines

8.2 Preventing Contamination of Water Supply

Cost and Affordability

9.1 Initial Investment and Long-Term Savings

9.2 Comparison with Electric Pumps

Environmental Impact

10.1 Eco-Friendly Nature of Manual Pumps

10.2 Sustainability in Water Usage

DIY vs. Store-Bought Pumps

11.1 Pros and Cons of DIY Installation

11.2 Benefits of Purchasing Pre-Made Pumps

Troubleshooting Common Problems

12.1 Identifying and Fixing Leaks

12.2 Addressing Low Water Flow Issues

Future Trends in Manual Pump Technology

13.1 Innovations in Design and Materials

13.2 Integration with Modern Water Systems

14.1 Summary of Key Points

14.2 Final Thoughts on Manual Hand Pumps